White fused alumina powder can be used for polishing floating oil seals primarily due to its unique physical and chemical properties, which are highly compatible with the material requirements and stringent surface finish requirements of floating oil seals. The specific reasons are as follows:

1. High Hardness and Excellent Wear Resistance

Properties of white Fused Alumina powder: The main component of white fused alumina is α-alumina (Al₂O₃), with a Mohs hardness of up to 9.0, second only to diamond and silicon carbide. This allows it to effectively cut relatively soft metals or ceramic materials.

Materials of Floating Oil Seals: Floating oil seal rings are typically made of high-hardness cermets (such as tungsten carbide WC) or special alloy steels. These materials are inherently hard and wear-resistant, but higher surface finishes can be achieved through precision polishing. The hardness of white fused alumina is sufficient for effective micro-cutting and grinding of these materials.

2. Sharp Edges and Self-Sharpening

Particle Morphology: After crushing, white fused alumina abrasive forms multi-faceted, sharp particles with sharp cutting edges.

Self-sharpening: During polishing, the particles are less prone to dulling due to wear; instead, they break and create new sharp edges, maintaining continuous and stable polishing efficiency and resulting in a uniform surface.

3. Good Chemical and Thermal Stability

Chemical Inertness: White fused alumina powder does not readily react chemically with the workpiece material, preventing contamination or damage to the sealing surface during polishing.

High Temperature Resistance: Under the high temperatures generated by high-speed polishing, white fused alumina maintains stable performance, without phase transformation or softening, ensuring the reliability of the polishing process.

4. High Purity and Low Contamination

Low Impurities: White fused alumina powder has an extremely high alumina content (typically >99%) and extremely low impurity content (such as Fe₂O₃).

Key Significance: This is crucial for polishing floating oil seals. Impurities may detach and embed into the relatively soft sealing surface during polishing, forming “embedded contamination.” In subsequent use, these hard impurities can severely scratch the sealing mating surfaces, leading to seal failure. High-purity white fused alumina significantly reduces this risk.

5. Controllable Particle Size and Uniformity

Precision Grading: White corundum abrasive can be precisely sieved into different particle size ranges according to the requirements of the polishing process (e.g., rough polishing, fine polishing).

Uniform Particle Size: The concentrated particle size distribution helps to form uniform and fine scratches during polishing. Through progressive refinement, a near-mirror-like ultra-smooth surface can be obtained, which is crucial for achieving zero-leakage sealing of floating oil seals.

Specific Polishing Requirements for Floating Oil Seals

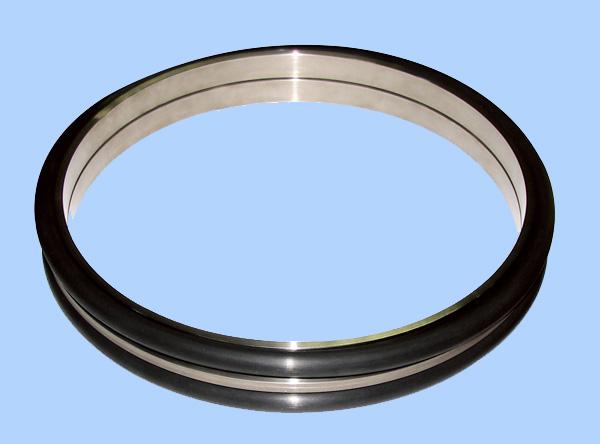

Floating oil seals are high-performance end-face sealing devices used in the drive shafts of heavy machinery (such as tractors and excavators). Their sealing effect does not rely on rubber rings, but rather on the tight fit of two highly smooth and flat end faces of two high-hardness metal rings (dynamic and stationary rings).

Extremely high surface finish requirements: Typically, a mirror finish (Ra value below 0.1 micrometers or even 0.05 micrometers) is required. Any tiny scratch or pit will disrupt the integrity of the liquid film, leading to leakage.

High material hardness: Sealing rings are mostly made of ultra-hard materials, requiring abrasives with even higher hardness for effective machining.

Strict cleanliness requirements: Hard particulate contaminants that could cause scratches must be completely eliminated.

Summary

White fused alumina powder, with its ultra-high hardness, sharp cutting edge, excellent chemical and thermal stability, high purity, and controllable particle size, is the ideal abrasive for polishing high-hardness, high-precision, and high-cleanliness sealing elements such as floating oil seals. It can efficiently remove material while minimizing surface damage and contamination risks, ultimately helping floating oil seal rings achieve the perfect mirror finish necessary for superior sealing performance.